PRESSURE VESSELS

PRESSURE VESSELS

Industrial Filter Manufacturers Inc. manufacturers a variety of pressure vessels for air / gas and liquid applications. All vessels can be constructed to meet ASME Boiler and Pressure Code requirements for unfired pressure vessels. Pressures from full vacuum to 3000 PSIG are available. Standard features include:

- In-Line connections for ease of installation and low pressure drop

- Service without breaking pipe connections

- Large volume sump area for collection of contaminants below the filter element

- Pressure taps on inlet and outlet connections

- Positive seals

- A "radial fin" element that pressure drop and large dirt holding capacity for long element life

- Duplex systems also available.

AIR/GAS

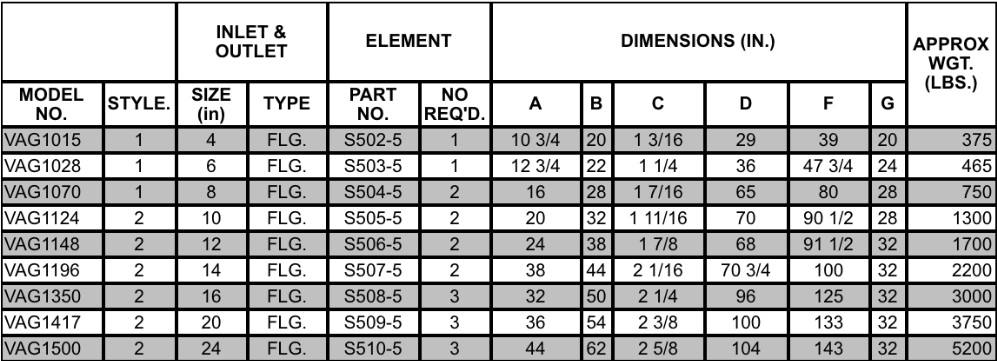

VAG Series Air & Gas Pressure Vessels

Connection Size: �" to 24"

Flow Rate: Up to 100,000 SCFM

Efficiencies: To 0.3 microns and larger @ 98% nominal

These models are designed to remove dust, dirt, pipe scale, and other contaminants from compressed air and gas pipelines.

The VAG SERIES provides positive protection for pneumatic controls, meters and other pipeline equipment The vessel design allows for mechanical separation of dirt and other contaminants into a large-volume sump area. Thus, increasing the life of the filter element.

SUPPORT LEGS AVAILABLE ON ALL MODELS. Dimensions are in inches and are approximate. Subject to change without notice.

LIQUID

VLS Series Liquid Pressure Vessel Filters

Connection Size: �" to 12"

Flow Rate: Up to 36,000 GPM

Efficiencies: To 1 micron @ 98% efficiency

Designed to effectively remove dirt, pipe scale and other particulate from water, liquid chemicals and petroleum products in liquid pipeline applications. Units are supplied with heavy-duty sewn end "radial fin" elements designed exclusively for use in liquid applications. All models provide a large-volume sump area for collection of contaminants below the filter element. Liquid duplex system shown.

COALESCING

VFS Series Coalescing Pressure Vessel Filters

The VFS SERIES filters are designed for separation of oil, water and other liquid aerosols, as well as solid particles from compressed air and gas lines. This model utilizes one or more high efficiency coalescing filter elements that provide clean, dry oil-free air that is essential in many critical applications.

Unlike standard in-line filters, coalescing filters carry air flow from the inside out: contaminants are captured in the filter matrix and collect together into larger droplets through collisions with the glass micro fibers. These droplets eventually emerge on the outside of the filter element where they are drained away by gravity.

VACUUM

VVS Series Air & Gas Pressure Vessel Filters for Vacuum Service

Connection Size: �" to 24"

Flow Rate: Up to 100,000 SCFM

Efficiencies: To 0.3 microns and larger @ 98% nominal

The VVS SERIES provides positive protection for all types of pumps in vacuum service. Each unit is individually tested to assure vacuum tightness. The vessel design allows for mechanical separation of dirt and other contaminants into a large-volume sump area. Thus, increasing the life of the filter element.