KNOCK-OUT POT

KNOCK-OUT POT

Vagau Series Knock-Out Pot/Inlet Filter

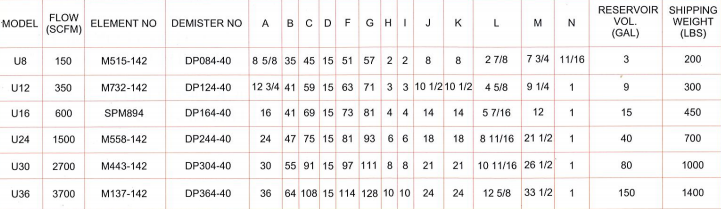

Model U8 - U36

Connection Size: 1" Thru 18"

Flow Rates To 135 to 4,000 SCFM

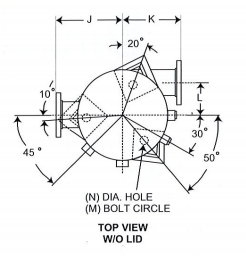

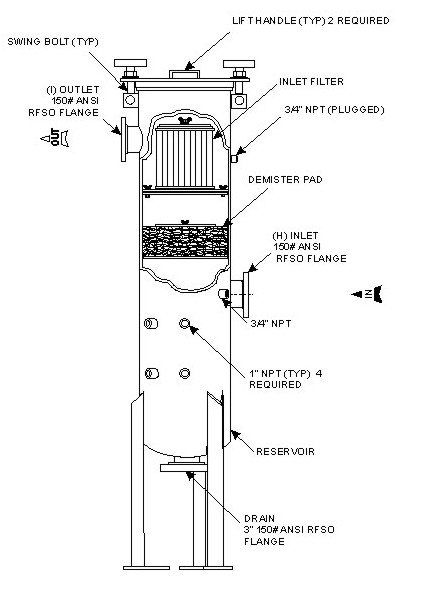

TANGENTIAL INLET

3" DRAIN AND 3/4" VENTS

DEMISTER PAD

CONNECTIONS FOR SIGHT GLASS/LEVEL SWITCHES

LARGE DIRT AND LIQUID RESERVOIR

QUICK OPEN LID

The Industrial Filter Manufacturers KNOCK-OUT POT/INLET Filter Series are designed to effectively remove liquids an/or particulate from the process gas of industrial equipment.

VESSEL CONSTRUCTION

Standard operating pressure and temperature of all VAGAU models is 15 PSIG and 300 degrees Fahrenheit. Inlet/Outlet connections are 150# ANSI raised face slip-on flanges. The vessel de sign provides for mechanical separation of mist, liquid and other contaminants into a large volume sump area, reducing the contaminant load and increasing the filter element life.

VESSEL OPERATION

The separation of entrained materials is accomplished in three stages. The first stage removes the bulk liquid by the centrifugal motion of the gas stream as it enters the vessel through a tangential inlet. In the second stage, a demister removes small liquid particles of mist and also acts as a pre-filter for particulate. Properly selected, conventional pads are ideal in most applications. At the moderate vapor velocity and liquid load for which a pad is designed, liquid trying to escape collects in a thin, flooded layer at the bottom of the pad. Bubbling causes re-entraininment of liquid, compounding the mist load. Virtually all droplets large enough for the wire to capture are eliminated in the lower half of the pad. The upper part, inactive as yet, is available for increased loads. The third stage is a particulate filter which removes solids with a standard efficiency of 98% of 5 microns.

ELEMENT CONSTRUCTION

Radial Fin filter element standard construction includes a durable felted polypropylene medium rated at 98% efficiency on 4 microns and larger. When conditions demand, alternate media of synthetic fibers or glasses can be supplied from .3 to 100 microns nominal retention